Wellwatch: Injection integrity monitoring

Real-time seismic monitoring is used to improve decision-making and safety during well drilling and injection operations. For those applications, a short reaction time is required. Reach Subsea's integrated solution to process seismic data and provide the required interpretation capability in real-time.

Injection of fluids in the subsurface is a frequent operation in hydrocarbon producing projects. Injection can have different objectives:

- Increase pressure in the producing formation to boost hydrocarbon recovery

- Dispose of wastewater and cuttings from well drilling

In both cases, Reach Subsea WellWatch systems provide:

- Monitoring of caprock integrity and fault reactivation for a safe injection

- Possibility to increase injection flows and capacity due to the improved safety

- Mapping of plume migration

- Monitoring of crack formation for prevention of water breaktrough into producing wells

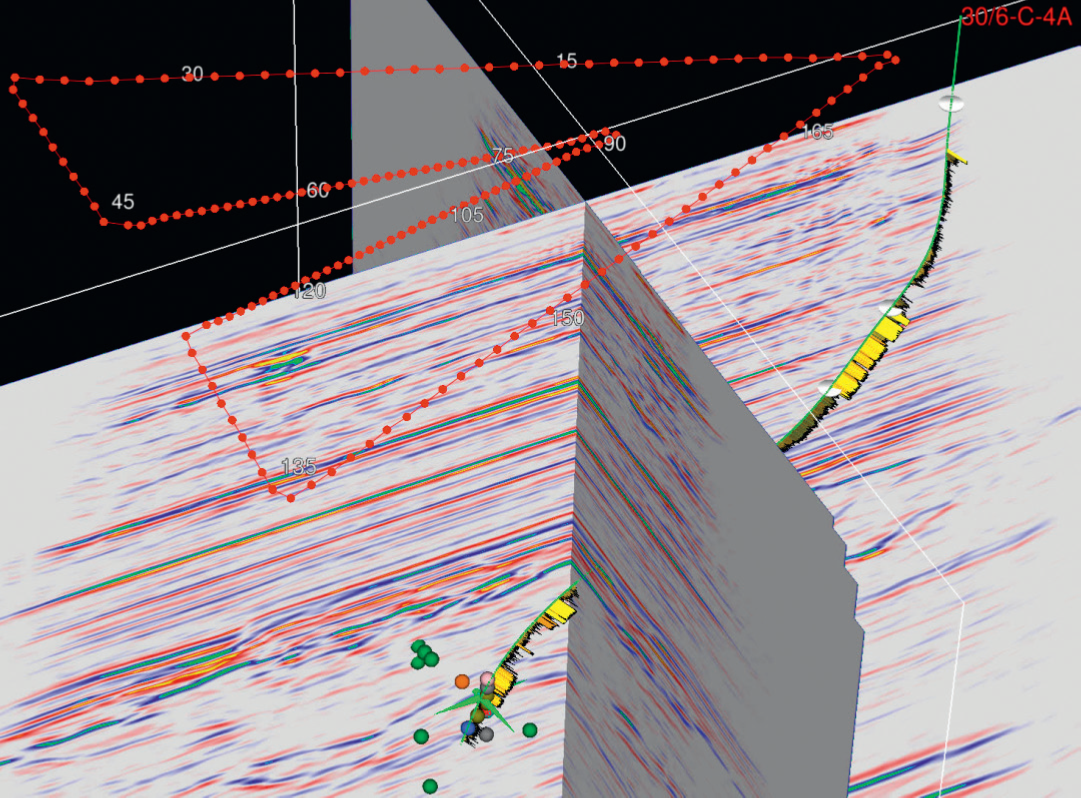

In WellWatch projects, data is analyzed in real-time, and feedback is provided to the client by means of Reach Subsea’s Guardian software.

The Oseberg field case

A 172-node WellWatch system is operating 24/7 at the Oseberg field since 2013.

This was the first offshore system word-wide with microseismic monitoring as main motivation.

The system is saving the operator 1.2 M$ per year, by enabling injection of waste water, and avoiding costly, weather-dependent shipping of waste to land.

A part from its main motivation of detecting microseismic events, the Reach Subsea WellWatch system at Oseberg has been used to:

- Significantly improve the imaging of regions of the reservoir by using active seismic

- Investigate gas leakages on the shallow sediments through interferometry

- Investigate detectability of CO2 through changes in sound velocity in water