Reach Subsea strongly believes in systematically implementing Quality and HSE measures, starting with early Project Risk Assessments and continuing through ongoing risk management processes.

At the sharp end, both access to information and each individual’s understanding of risks are critical. We therefore require that clients, third parties, and subcontractors provide the necessary information to the workforce when planning or executing subsea operations involving risk.

Commitment to compliance stems from a strong HSEQ culture. At Reach Subsea, we believe such a culture is built on respectful and constructive dialogue. Our leaders are expected not only to be technically competent but also to demonstrate strong interpersonal skills.

Whistleblowing channel

You can use our whistleblowing channel, to report suspected misconduct and wrongdoings in our organisation. The aim of our whistleblowing channel is to provide a better opportunity to disclose various forms of misconduct, as well as to provide enhanced protection for the reporting person.

HSEQ Standards

Reach Subsea operates in accordance with the following industry HSEQ standards and certificates.

Achilles FPAL/Global Energy ID

39873 (UK)

Achilles UVDB ID

21589 (UK)

Achilles JQS supplier ID

37245 (Norway)

Magnet JQS supplier ID

2009 (Norway)

SeQual supplier ID

1520 (UK)

ISO-9001-, 14001- and 45001 certificates

Reach Subsea Policies

At Reach Subsea, we recognize that clear and well-developed company policies are essential for ensuring consistency, safety, and quality across all our operations. They provide our teams with guidance, support informed decision-making, and create a strong foundation for our HSEQ culture.

Reach Subsea Code of Conduct

Code of Conduct 2025

We’re always striving to improve our ethical business practices and personal conduct, to read more, please download our Code of Conduct here:

Risk Management

Risk management is a key tool for monitoring and controlling the rapid changes our business is exposed to. At the corporate level, formal risk and opportunity reviews are conducted monthly to identify major changes and define the necessary risk-reducing actions. All projects undergo a risk and opportunity evaluation covering operational, commercial, and HSE aspects, with the HSEQ Department responsible for monitoring the corresponding mitigation measures.

Employee Involvement & Competence

In addition to participating in risk assessments, employees take part in HSEQ meetings, audits, inspections, Working Environment Committee meetings, and board-level employee representation. All employees receive HSEQ training tailored to their specific work tasks and associated risk exposure. Once a year, onshore and offshore management come together to share lessons learned, and to discuss and agree on strategies for the year ahead.

Reach Subsea has developed its own e-learning system – ReachED. This platform provides an excellent opportunity to deliver tailored internal courses designed for our industry, while also offering training opportunities for our suppliers.

IOGPs 9 Life Saving Rules

The IOGP 9 Life-Saving Rules are vital because they focus on the most common causes of serious injuries and fatalities, helping everyone work safer and go home unharmed.

Safety

A safe delivery of subsea services starts with active involvement of the offshore work force in the planning process. The competence of each individual approved to work for us, represents the technical integrity we need to operate safely. Reach Subsea therefore safeguard our people, and give them all necessary support in their search for the safest and most optimal solutions.

Environmental Management

Reach Subsea continuously work to have a sustainable business strategy. Our target is ZERO spill to the environment. We emphasize the use of environmentally friendly solutions, both technically and operationally, choosing modern assets and technology. We also work constantly on reducing the amount of environmentally hazardous chemicals onboard.

Suppliers are encouraged to reduce the environmental footprint and are committed to achieve energy efficiency. Reach Subsea encourages the owners of our vessels to install battery packs to reduce fuel emissions and be more energy efficient. Any impact on the environment is reported and followed up to prevent reoccurrence.

Security

Our operations are constantly expanding geographically, exposing us to changes in the global risk landscape. This requires us to continuously assess emerging risks, adapt our safety and security measures, and ensure compliance with local regulations. By staying vigilant and proactive, we protect our people, assets, and reputation while maintaining operational excellence across all locations.

Quality

Quality is at the heart of everything we do, ensuring safe, efficient, and reliable operations while meeting the highest standards for our people, clients, and the environment.

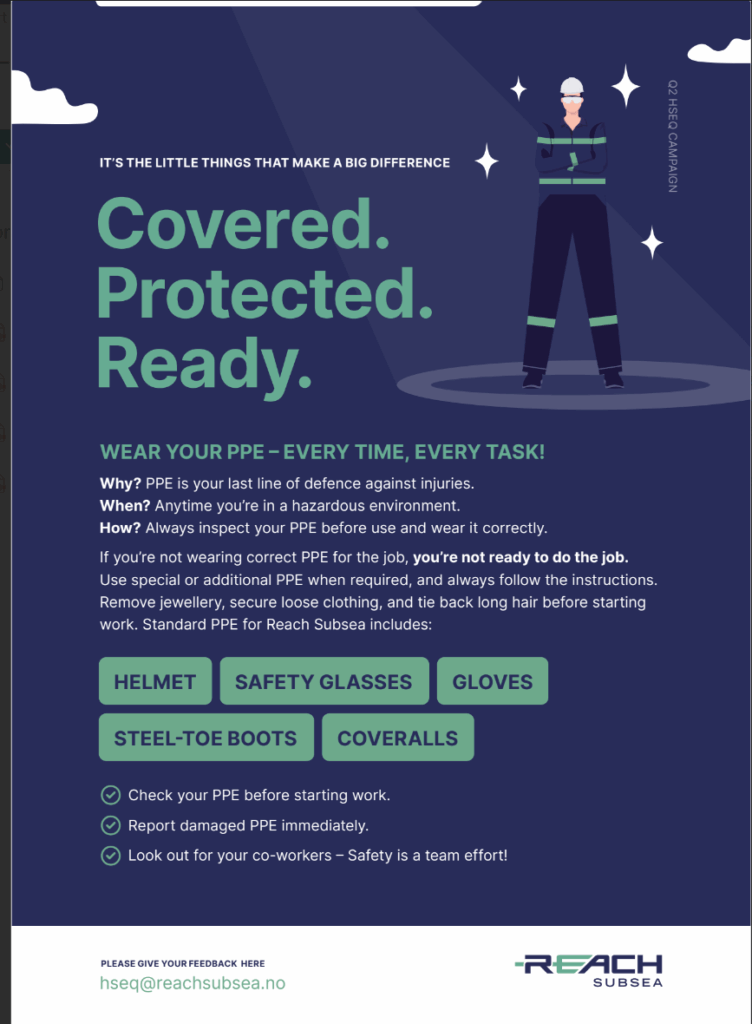

HSEQ Campaigns

Our continuous HSEQ campaigns help maintain awareness, reduce risks, and strengthen our HSEQ culture. They support compliance, improve efficiency, and show our commitment to people, safety, quality, and the environment.

2025

Q3 2025

Q1 2025

Q2 2025

Would you like to talk to us about HSEQ?

We would like to have you aboard. If you have any questions, please feel free to contact HSEQ Manager, Sigbjørn Aga.